As you know, the month of April is dedicated to getting Adventure ready for the season. One of the obvious things we do is check all the navigation lights. To our surprise the bow light was not working. I immediately came to the conclusion that the bulb had probably burnt out, mostly motivated by the fact that I was cold and wanted to go back inside.

The next morning we observed that a fix I’d done poorly years ago had come back around. That’s the nice thing about a boat, if something is fixed poorly you’re guaranteed an “opportunity” to do it again.

I told Kathy the bad news that the wires were broken and that it was a complicated fix. I explained that we travel in the day now and we didn’t REALLY need a bow light. Full of distrust of her subordinate, Kathy went forward to inspect the problem herself. “Come on!” she said. “It should only take 1/2 hour to fix.” But I knew the dark truth – it was going to take much longer. Much, much longer. I shuddered knowing of the pain that would soon follow and wondered if there was a way I might get promoted to management.

At the bow, Kathy could see the small nubs of wire sticking out of the hole in the bow pulpit, like two fledglings peeking out of the hole of a tree. As she reached for them, afraid, they retreated out of reach. “Go get me some needle nose pliers,” she commanded. I rushed back to retrieve the desired articles, not having much confidence that it would result in something meaningful. As I’ve explained earlier, I’d done the previous fix.

I heard a metaphorical squeak as she grabbed hold of a wire with the pliers. But the wire was able to break free from its predator and retreated further out of reach.

I opened the anchor hatch and reached for the deck plate. It’s round and has two indents for your fingers to turn it. Kathy ignored me, futilely focused on retrieving the bashful nubs of wire. I tried to turn the deck plate but it didn’t move. I pressed with all my might summoning the power of the universe and my finger slipped and banged against something hard. I winced in pain, my eyes began to water. Kathy noticed NOT!

I waited for the swelling of my fingers to begin and tried again. It moved a quarter turn. Unfortunately, it needed to move more. A lot more. I saw screws holding the deck plate on and changed tactics. In short order I had removed the deck plate…entirely.

The wires were right there in front of me. I felt a sparkling of pride as I told Kathy that I now had access. “Good,” she said snapping the needle nose pliers in her hand in an obvious dominance move. I tried to ignore it. I put my hand through the hole and pushed on the wires but nothing happened. This is what I had remembered from previous attempt to fix it, and why the original fix had been done so poorly. “They won’t move,” I said. Kathy gave me a very sad and disappointed look. She used small hand gestures to explain it like I was five, “Just push the wire up the tube.”

After explaining again that the wire did not move, I tried pulling the wire. It did not move. I decided to pull harder. It did not move. I wrapped the wire around my hand and pulled with all my might. Veins began to pop out of my neck. It did not move. Kathy, unimpressed by my efforts began to make accusations of fakery.

After taking pictures and me desperately trying to convince Kathy that I was indeed pulling the correct wire and not one (on the right) that was zip tied to the hull we stood there dumbfounded.

Kathy decided to call it quits mumbling something about the incompetence she had to work with, and went down below. Now I was all alone. I contemplated my next move. It was time to remove the screws holding the leg to the bow pulpit. There were only two of them. But they were from the original factory install, circa 1989.

I quickly retrieved my electric screwdriver . As I engaged the driver and began to see the screw move I mentally patted myself on the back. But at that very moment the head of the screw sheared off. I looked around to see if Kathy had witnessed what had occurred. I was in big trouble. I needed to cover this up fast. I tried to think of options: tape, superglue? She’s going to notice. Hundreds of images from Leave it to Beaver flashed through my head. Burn the boat! Burn the boat! There’s no getting out of this! I sulked back to the saloon to tell Kathy the bad news.

After a lecture about using an electric screwdriver, I grabbed a manual one and ran back up to the bow to redeem myself. I slowly turned the screw and it began to move. Only one screw is broken, I thought. It’s only one screw. But then the head fell off the second screw. Darn It!

We pulled the pulpit mounting leg up and saw the issue. A giant wad of silicone had been placed over and around the wire to prevent water from going down the hole. Part of me appreciated the attention to detail. Most of me wanted to kill the person that did it.

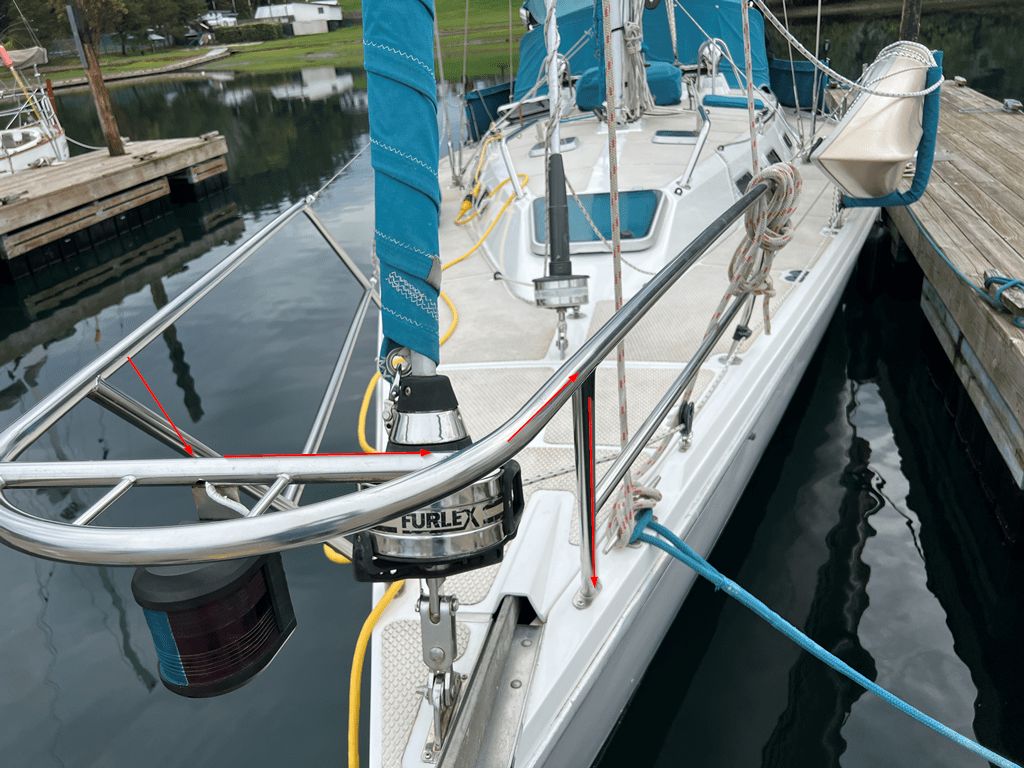

After removing the silicone, and beaming with pride to have found the issue, I began to pull the wire out. Kathy, not noticing what I was doing until it was too late, screamed in horror, “NO!!!!” I had pulled the wire further down the tube and away from the exit hole. Kathy looked at me with disgust. The wire makes two turns through the stainless steel tubing (see red arrows in photo). We could probably make one turn with the new wire, there’s no way we’d make two.

Kathy left so I could focus on getting the broken screws out. I hatched a plan to drill around the shaft of the screw and try and grab it with trusty vice grips. The first part of the plan worked great. Unfortunately, grabbing the shaft with the vice grips did not work. The shat being very corroded kept breaking. I decided to drill around the screw shaft and after breaking my drill bit found a 1/2 inch thick aluminum plate buried 1/2 inches under the fiberglass. I retrieve a larger drill bit and worked my way around the shaft. Then it got violent! I took a hammer with a small screwdriver and broke out the small bits between the holes I made around the shaft. The bolt finally gave way. I then did the same for the other side.

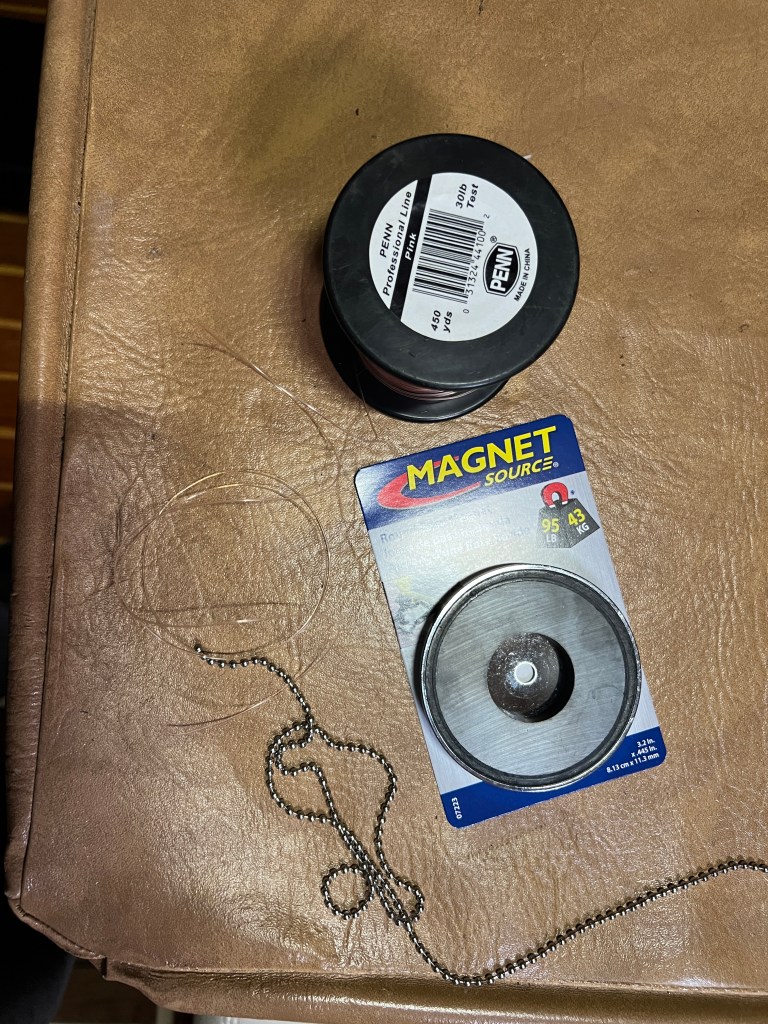

Meanwhile, Kathy researched how to run a wire around two turns inside a stainless steel tube. Kathy settled on a magnet, a small section of lamp chain, and some fishing line. She was able to pull the lamp chain with the magnet and pretty easily ran it through the tubing. Soon after we had new wire pulled through.

The aluminum plate, riddled with holes, no longer seemed viable so we decided to thru-bolt the new screws. We first made new clean holes with the drill and then filled both with epoxy mixed with bits of fiberglass and Cabosil. When it started to rain, we covered the mess with tape and went inside to work on something else.

After the epoxy cured we used a Dremel tool with a drum sander attachment to sand down the epoxy. We then drilled new holes and, sealed with a lot of butyl tape, bolted the post back in place. So now we have a working bow light. It was easy. It only took 3 days. Typical boat project.